SERVICES

Testing

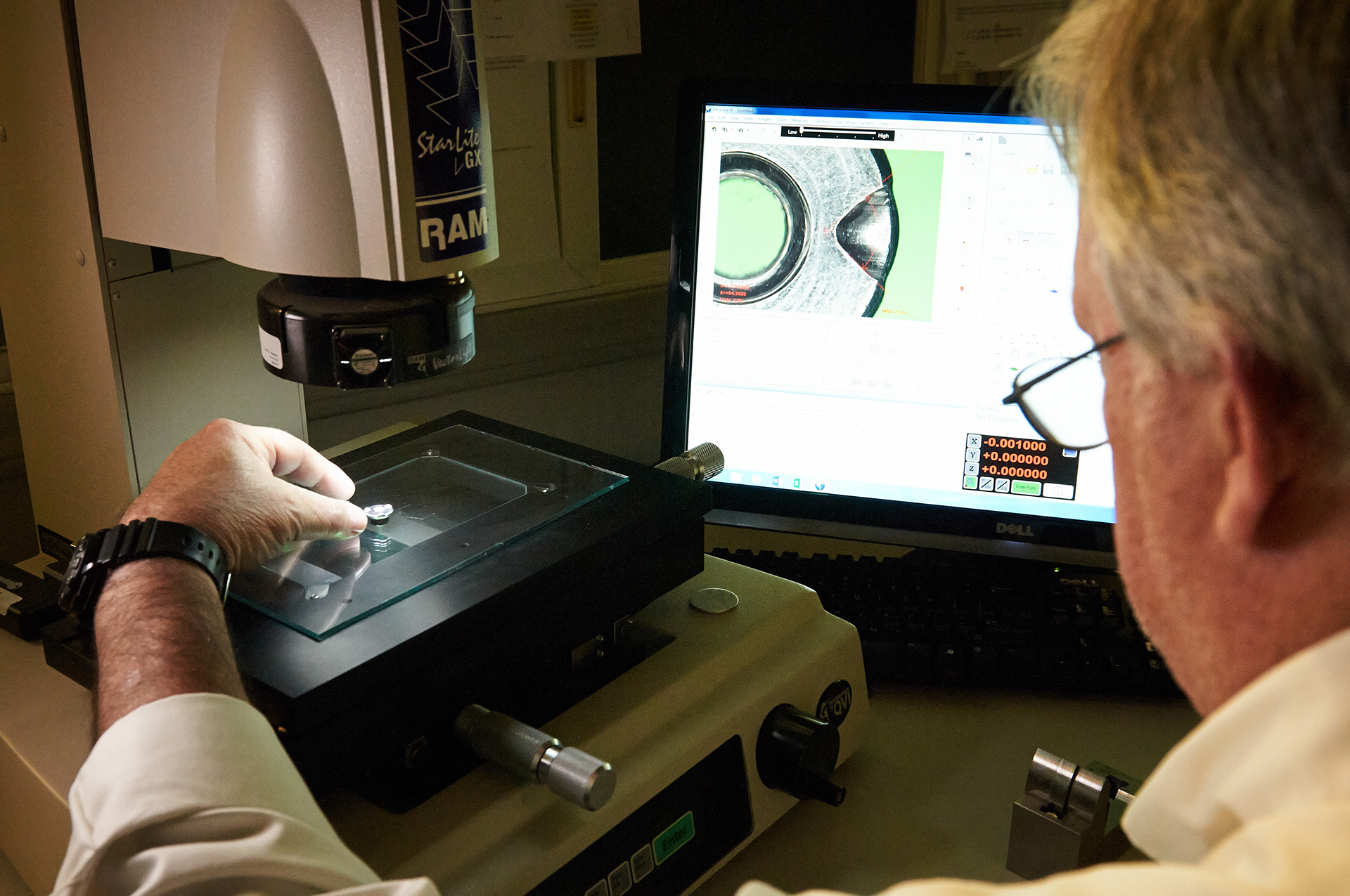

You have access to some of the best testing available to accurately measure and evaluate performance for your specific application. At Ram-Bul we will help you understand how and why a part functions and help you make sure it is the correct application, in the right place at the right time. Our quality and testing process includes functional checks, material testing and steps to maintain 100% quality for each part.

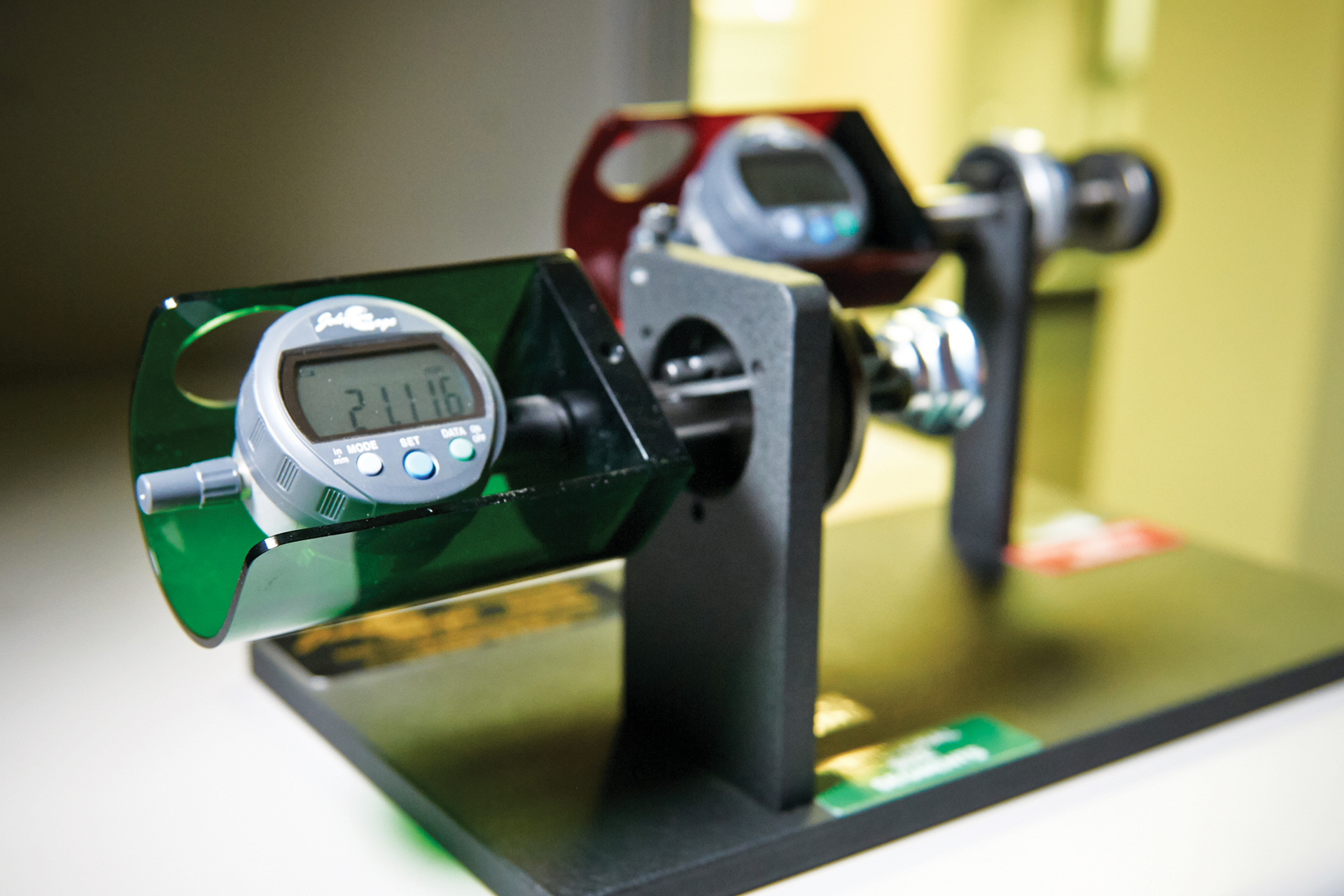

This includes functional testing of friction values by your standards, and we test for roughness, corrosion, and screw-in and screw-head torque. Reviews of functionality also include dimensional, shape and position measurement and measurement of patches.

Material testing includes spectral analysis, tensile according to DIN EN ISO 898-1 + 6892 up to 400 kN, and hardness testing according to Brinell, Vickers and Rockwell. We measure surface layer thicknesses and conduct leak testing of patch surfaces.

Due to quality processes such as in-house sorting, we can control completely for every part, minimize wrong or damaged parts, and secure the world-class quality of your fasteners. We understand that such control is crucial for critical processes such as automatic assembly.